Snapshot

- Delivered High-Performance Computing (HPC) for quickly and efficiently problem-solving automotive manufacturing challenges and innovating aerodynamic design.

- Enhanced the ability to perform computational fluid dynamics (CFD) simulation in the cloud and extract the results to make data-driven decisions.

- Scaled private on-demand data flows between on-premises infrastructure connecting to SAP workloads across multicloud regions.

- Enabled scaling from 200 to 5,000 compute cores in the cloud, in a matter of minutes.

- Optimized network connectivity between on-premises and public cloud to bring the team’s vision to reality, and progress the next generation of luxury electric cars.

About Karma Automotive

Karma Automotive is a Southern California-based automaker of world-class extended-range electric cars designed to challenge habitual thinking about luxury. The automaker is creating history; reshaping vehicle experiences through innovative design, technology, and customization.

Challenges

New thinking and new technology are what Karma Automotive needed to bring their vision to life. Innovating luxury automobiles with uncompromised dynamics, impeccable handling, and intelligent technology and energy recovery is one challenge, but ensuring the systems ‘under the hood’ are optimized to bring the design and manufacturing to reality, is another.

Visualization is a core component of any design and manufacturing process. And when it comes to putting Karma Automotive’s tireless ambition and eccentric style into practice, visual data and simulations are key. The team needed tested, transparent, and data-driven techniques to ensure concept cars were performing as they should, to analyse the performance of new models, to perfect safety and efficiency, and to progress innovation and design, while upholding their reputation for pushing the boundaries of their field.

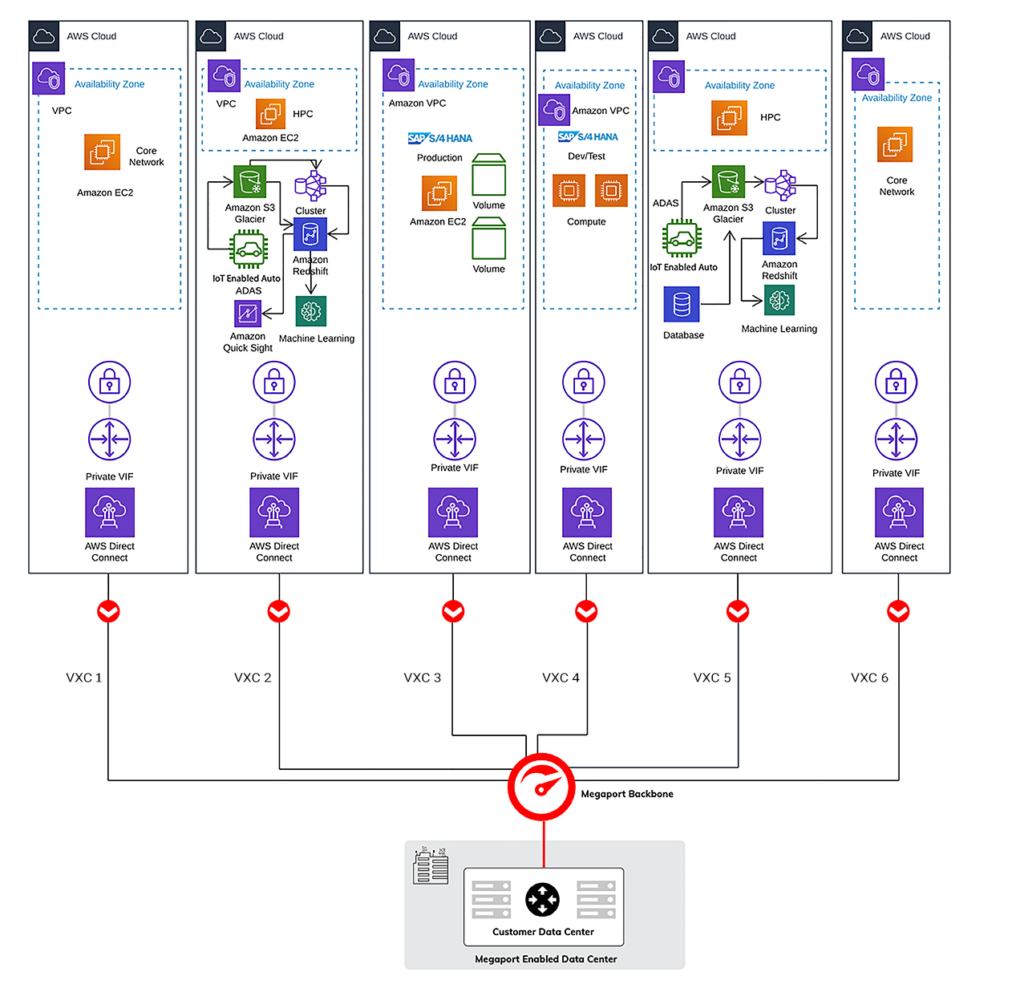

Karma Automotive’s existing network architecture consists of production databases and steady-state workloads based in colocation facilities – while their aerodynamics studies and manufacturing designs are hosted on AWS EC2 instances for HPC. They needed an optimized and efficient way of performing CFD simulation in the cloud and extracting the results to feed back into their creative concepts. With disparate work environments, and no dedicated way to connect between them, accessing the real-time data they needed – to inform the production of their luxury electric cars – was the challenge.

- The team’s automated craftsmanship process requires real-time data transfer from their Higher Performance Compute and SAP environments – hosted in AWS – that allow their torque wrench machines to measure and assemble vehicles.

- Processing data analytics using AWS hybrid cloud would enable Karma Automotive to study and innovate Crash Analysis and Thermal data to keep cars efficiently safe.

- Bringing disparate environments together and enabling seamless, real-time data flow between cloud and colocation was a complex process.

- The Company requires easy, on-demand connectivity to scale large amounts of data between their legacy hosted and public compute cloud environments while managing costs.

Solution

Groundbreaking innovation is most often underpinned by flexibility – and doing things a little differently. Karma Automotive’s network architecture needed next-generation Network as a Service (NaaS) resources to solve the team’s connectivity challenges, so they could continue making great strides in refining and redefining the electric car industry. Megaport’s flexible, scalable, and dedicated Software Defined Network (SDN) made it possible for the team to transform their connectivity strategy, simplifying the way they move data between their on-premises and cloud environments.

- Karma Automotive created a seamless hybrid cloud strategy with Megaport’s NaaS services which enabled access to run real-time torque measurements in AWS using large compute instances, analytics, and big data applications.

- This enables efficient data flow between their disparate colocation and cloud environments which is enhancing their ability to perform CFD simulations in the right place at the right time.

- They can now scale private on-demand data flows between on-premises infrastructure connecting to SAP HANA workloads across multicloud regions.

- Calculations can be run multiple times for aerodynamics design and manufacturing studies.

- The team is now able to spin up hundreds of compute instances for HPC. They scaled from 200 to 5,000 compute cores, in a matter of minutes.

- These on-demand compute instances run simulations in the cloud for their team to extract the data results, deliver back to their on-premises infrastructure, and manipulate the data files on demand.

Benefits

Developing a modern network architecture to achieve an agile work environment is critical to Karma Automotive’s success. Operating a data-driven business that relies on next generation customer experience, car intel and manufacturing decisions between their physical compute infrastructure and public cloud workloads brought about many key benefits for the company:

- Reduced Total Cost of Ownership (TCO) by leveraging Megaport’s NaaS solution for accessing AWS’s large compute, analytics, and big data applications.

- Quicker, more reliable connectivity to the applications and platforms they needed to power their business and as a result, the ability to design and build luxury cars faster.

- Enhanced efficiency, safety, and innovative design within their cars through the ability to more efficiently process and study data on thermal and crash analysis.

“We leverage Megaport with our physical colocated infrastructure to deploy hybrid cloud connectivity which ensures low-latency communication between public cloud workloads and legacy databases in the data centre.”

Director, IT Infrastructure, Karma Automotive

Future Plans

Karma Automotive will continue to increase the amount of real-time data collection from their cars using Redshift and Data Lake within AWS to their physical colocated infrastructure with Megaport enabling their hybrid cloud connectivity. This will further inform advanced driver assistance, business reporting, vehicle health reports, and scale their consumer service business with their innovation. Megaport is dedicated to working closely with Karma Automotive, as a key factor in their network strategy, while the organization drives the future of luxury electric automobiles.